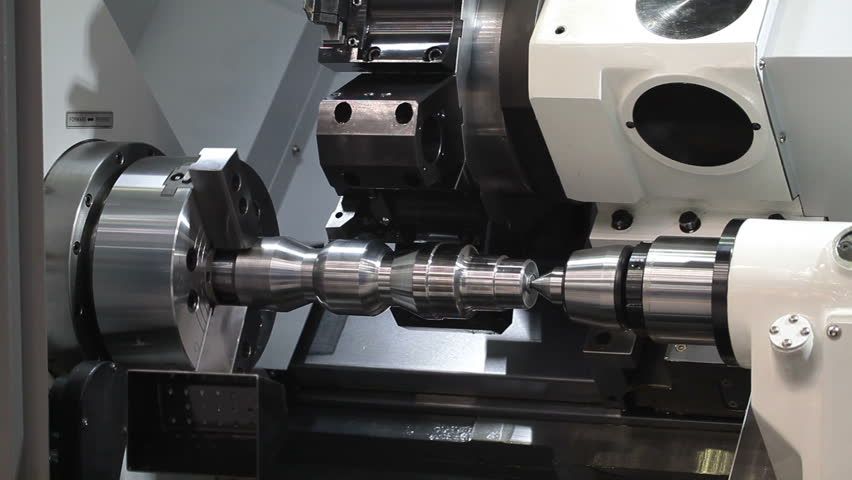

CNC Turning

With multiple networked Okuma lathes incorporating automatic operation and live tooling, we are able to quickly manufacture parts with tight dimensional tolerances.

Maximum diameter: 16 inches (406 mm)

Maximum length: 19 inches (482 mm)

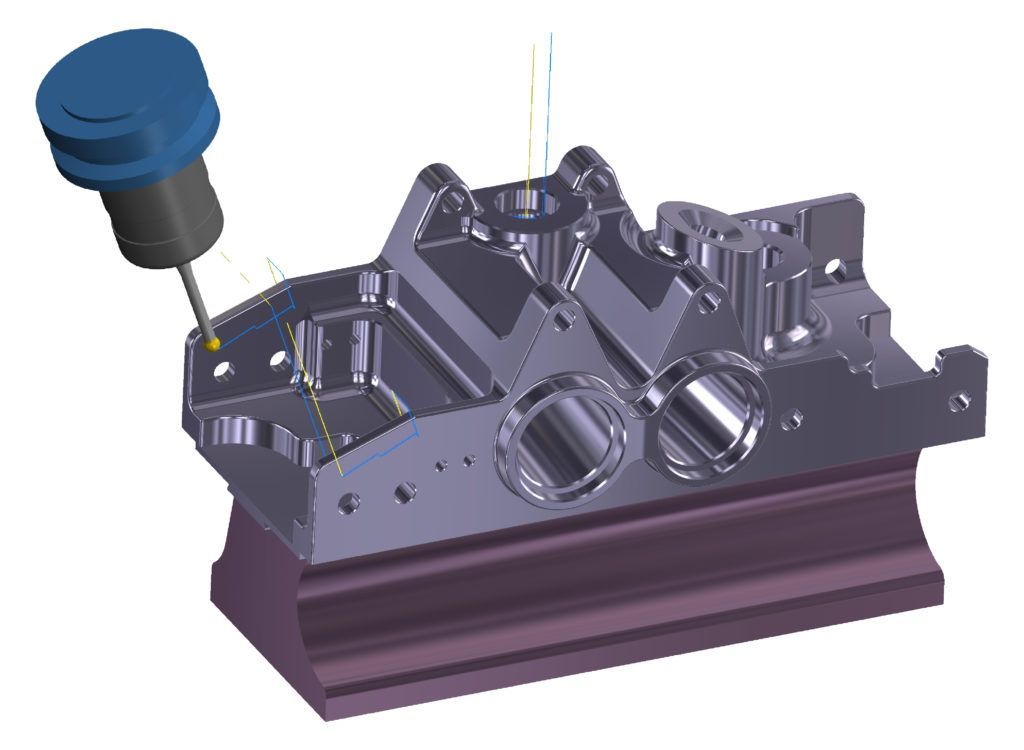

CNC Milling

Vertical milling up to 30″ x 17″, and larger depending on part features.

Inspection

We have a full suite of Mechanical Inspection equipment including a height gauges, calibrated granite tables, veniers, comparators, micrometers, profilometer, and slip gauges.

Traceability

Our shop floor operates on a QMS that is AS9100D compliant. Material certifications, process certs, and NADCAP compliance are all things we do every day.

Assembly

We regularly assemble parts to customer requirements. Let us know what you need!

Laser/Waterjet cutting

We work closely with cutting houses to minimize costs and lead time for you.

Grinding

We partner with the best grind shops to simplify your supply chain.

Heat treatment

If your parts require outside process heat treatment, let us take care of it for you.

Coatings and finshes

Anodizing, Zinc Nickel, Powder coat, black oxide, chromed, satin, tumbled, polished, …. Whatever your coating or desired surface finish, we can get the job done.

Design and Engineering

With a highly-skilled design and engineering team, our online CNC Design Services can turn your concept into reality, ranging from mechanical components to parts used in aerospace, automotive, electronics, military, medical, food, and many other industries. Even if you just have an idea of the final product, please tell us your detailed requirements or submit a sample, we’ll deliver a professional product design drawing based on your customization.